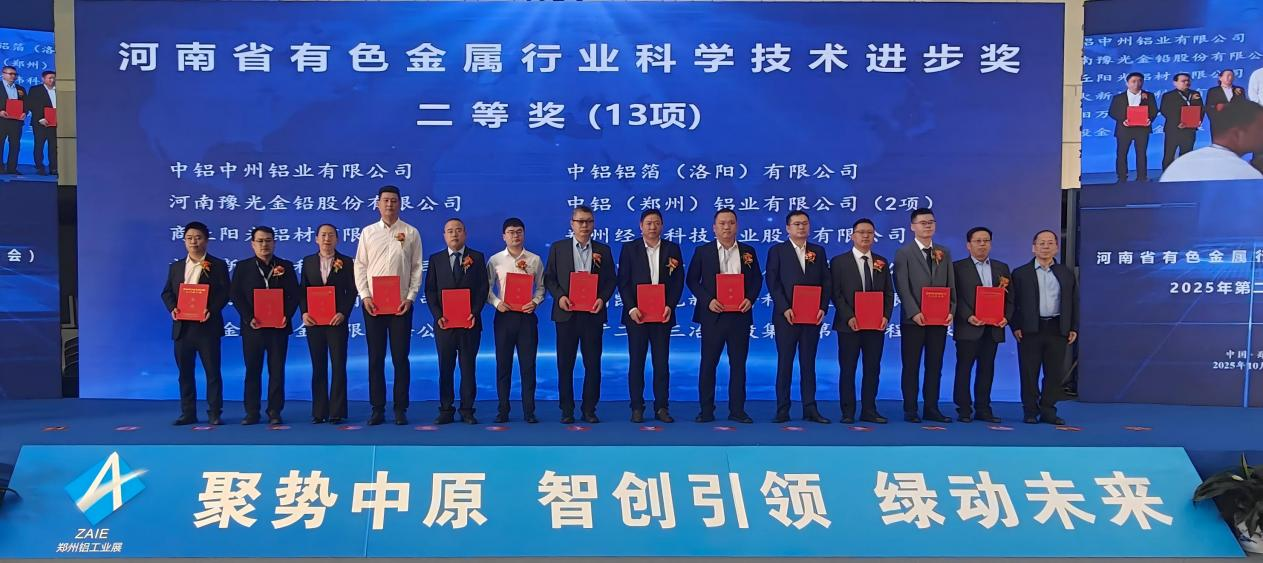

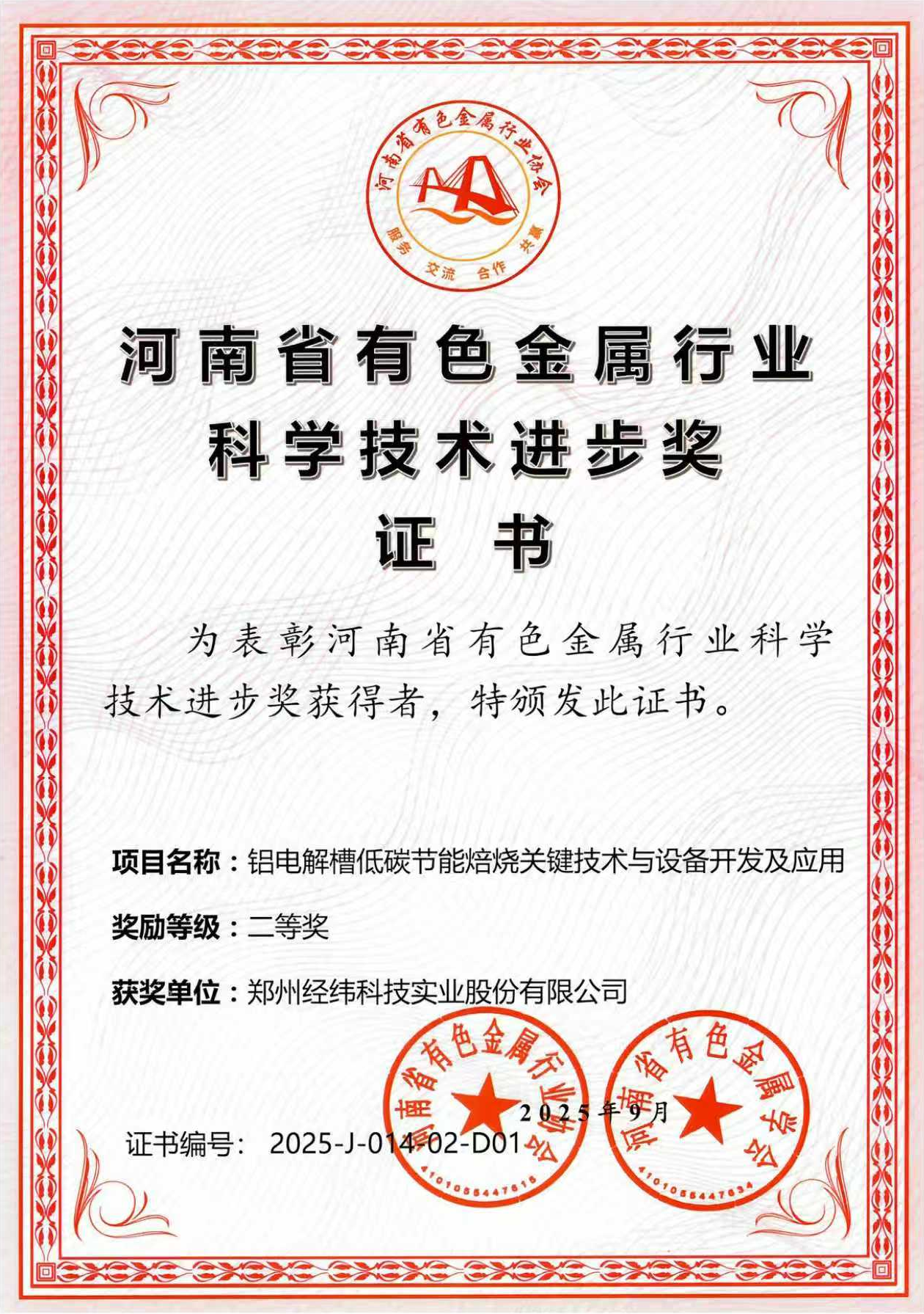

October 14 to 16 , 2025 , the the "3rd Central Plains (Zhengzhou) International Aluminum Industry Exhibition & 6th Central Plains International Aluminum Processing Innovation and Development Conference" were held at the Zhengzhou International Convention and Exhibition Center. During the event, the Henan Nonferrous Metals Industry Association presented awards to organizations and individuals that received the 2025 Provincial Nonferrous Industry Science and Technology Progress Award, the Excellent Patent Award, and the Henan Advanced Aluminum-Based Materials Industry Chain Science and Technology Innovation Leader Award. Zhengzhou Jingwei Technology Industry Co., Ltd. (hereinafter referred to as Jingwei Technology) won the Second Prize of Science and Technology Progress Award for its independently developed project "Development and Application of Key Technologies and Equipment for Low-Carbon and Energy-Saving Roasting of Aluminum Electrolytic Cells". The company's deputy general manager, Heng Jiatao, accepted the award.

"Development and Application of Key Technologies and Equipment for Low-Carbon and Energy-Saving Roasting of Aluminum Electrolytic Cells" is a scientific and technological achievement independently developed by Zhengzhou Jingwei Technology Industry Co., Ltd. It has 3 invention patents and 8 utility model patents with completely independent intellectual property rights, 1 CE certification, participated in the formulation of 1 group standard, and won 1 first prize of Henan Province Industrial and Information Technology Science and Technology Achievement Award. It has been recognized as an industrial energy-saving product in Henan Province and selected into the Henan Province Industrial Energy-saving Product Promotion Catalogue and the Henan Province Energy-saving, Low-carbon and Environmental Pollution Prevention and Control Technology Guidance Catalogue.

This achievement is an innovation technology in aluminum electrolytic roasting startup. It breaks through the traditional "coke particle energized roasting" method and innovatively adopts the "high-temperature flue gas precise temperature control + complete combustion of fuel in the pre-combustion chamber" design. The fuel achieves the best combustion effect, the cell cavity temperature is evenly distributed, and the contact between the open flame and the cathode and anode is avoided. It fundamentally solves the industry's technical problem of easy oxidation of the cathode and anode, and effectively extends the service life of the electrolytic cell. Through automatic control technology, a 9-stage heating strategy is designed to make the roasting temperature of the electrolytic cell adjustable and controllable, realizing automatic control management of the electrolytic cell roasting startup. This achievement is applied to the startup of new cells of ordinary cells, high-purity aluminum cells and shaped cathode cells, as well as the secondary startup of overhaul cells, planned shutdown cells, and accident cells. It has a high degree of automation and significantly reduces the energy consumption indicators of the roasting process.

With Jingwei Technology's continuous iteration and upgrading of flue gas roasting technology and equipment processes, the roasting effect and energy-saving performance have been optimized. The equipment has become increasingly lightweight with higher functional integration, significantly reducing roasting and startup costs and achieving stronger market competitiveness. This achievement has been applied in many domestic aluminum electrolysis enterprises and exported to "Belt and Road" countries such as Indonesia and Malaysia, making outstanding contributions to energy conservation and emission reduction in aluminum electrolysis.